Assembly Automations

- Home

- Assembly Automations

Custom Assembly Automation System Design, Manufacturing & Integration

Assembly Automations

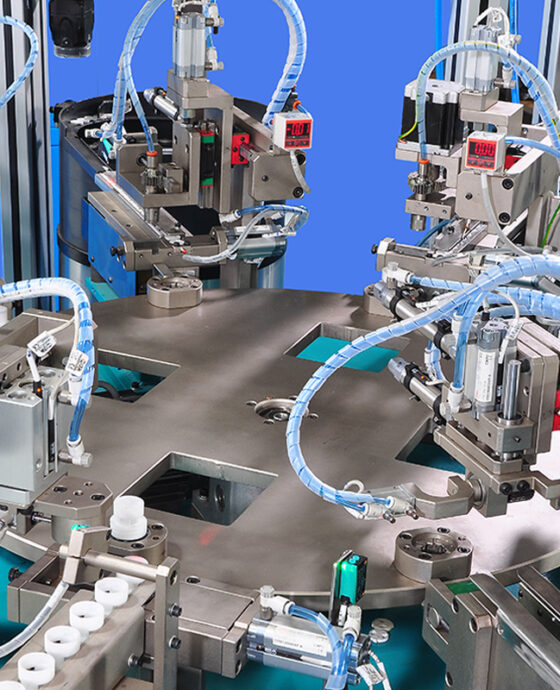

Elmech Automations designs and builds custom assembly systems to help manufacturers reach their full factory production potential.

We manufacture flexible, lean assembly equipment — ranging from manual workstations to fully-automated, turnkey assembly lines — that allow you to increase assembly process efficiency and profitability and improve product quality and safety.

Whether with a simple workstation or fully-automated assembly system, Elmech Automations technology reflects the utmost precision in robotics design, construction, and integration. It always aims at maximum process reliability and our objective is always the efficient solution of a complex assembly problem.

For our customers this means maximum modularity and flexibility in their assembly automation systems – accompanied at the same time by a high level of availability and re-useability. Elmech Automations assembly machines can always be adapted to new product versions or changing product life cycles.

Depending on the job in question, our systems deal with small and miniature parts at high output rates or heavy parts with a low output rates. A long working life and precision are the cornerstones of Elmech Automations assembly systems. We follow a very clear principle to never compromise on the quality and availability of the assembly plant and equipment which our team manufactures and delivers. This is our contribution to the continued corporate success of our customers.

Our in-house team of engineers and tradesmen work closely with customers to satisfy their requirements—from consultation and design to install, start-up and training. We immerse ourselves in product development, design, and product launch procedures and analyze all production steps thoroughly. We delve deeply into the processes of manufacturing a product before we offer a solution.

We have undergone the below testing systems

Elmech assembly systems are designed not only with design, structure and economic factors in mind — they also always take account of the return on investment over the entire life cycle of a machine.

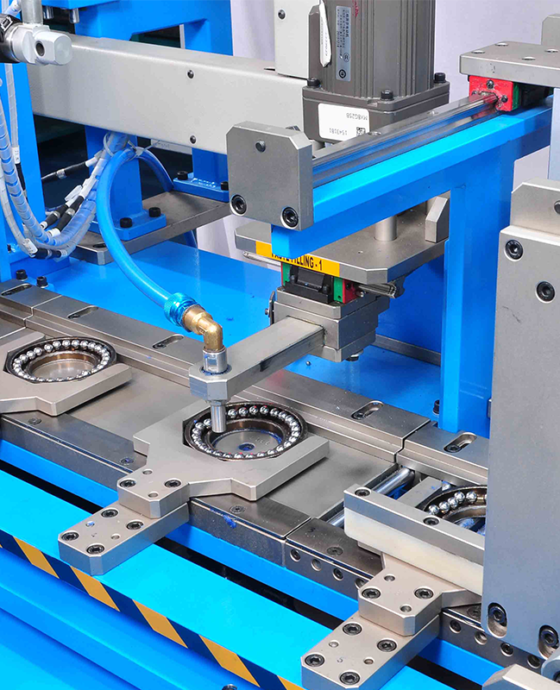

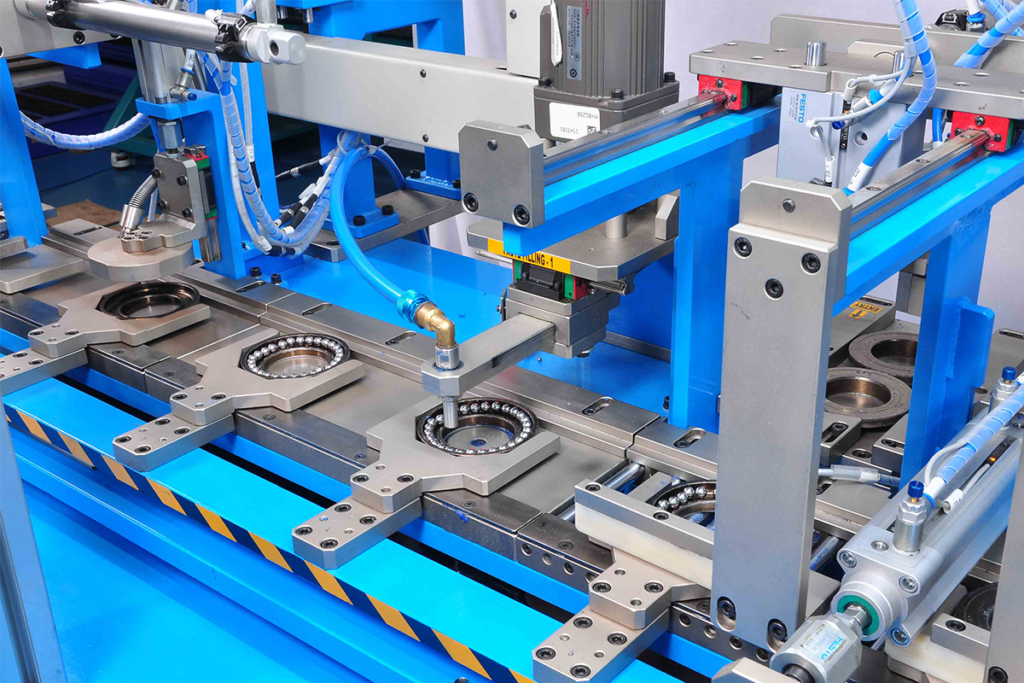

Here's a recent example of a big assembly system that we built for a

Product – 1200 RPM Spinning Spindle bearing assembly – 14 Component Automatic Feeding and assembly at a cycle time of 5 seconds per assembly

Product – Rocker Arm Needle roller Bearing Assembly – Assembly and Vision based inspection of assembled product at a cycle time of 3 seconds per assembly